Maptek general manager for North America, Rob Hardman was recently speaking with a senior operations figure at a big gold company when the latter remarked that, "you guys have a unique position here … you can get my geologists and engineers working together because they're all using Maptek products, and there is very little of that in my whole department".

And then, says Hardman, the question he most likes to hear: "What else can you do for us to streamline our processes and get everyone on the same page and working towards some of our bigger picture goals?"

That is exactly where Maptek's focus has been for the past few years. Now, coming out of a downturn which knocked the stuffing out of some big and small mining software groups, the company is strongly positioned to reap the benefits of sustained investment in its core products, and some very significant new ones. And continued investment in people: Maptek is at similar global staffing levels to when it went into the downturn. It has grown its market support footprint in Canada, Latin America and Africa.

And it has been working closely with key customers in Australia, where it is headquartered, North America and elsewhere to refine its future technology and services roadmap.

Maptek managing director Peter Johnson says the company has continued to invest in the flagship products that have become extensions of geology, engineering and operations offices around the world: Vulcan, Eureka, I-Site and the more recent additions BlastLogic and Sentry. Evolution, a scheduling product built around a unique genetic algorithm and originally developed for consulting applications, is not only reaching its full potential as a commercial mine and value-chain optimiser, but could be about to redefine the way users combine fleet and production optimisation with day-to-day mine planning.

"We have deep mining domain knowledge, technical expertise and engineering resources, and a proven history of leading technological shifts in the mining industry," Johnson says of the company founded in the 1980s by a serial entrepreneur and innovator, and former public exploration company head, Dr Bob Johnson.

"Maptek has been providing robust technical solutions that meet core business needs for many years and now we are working with long-term customers to deliver the digital transformation the mining sector needs.

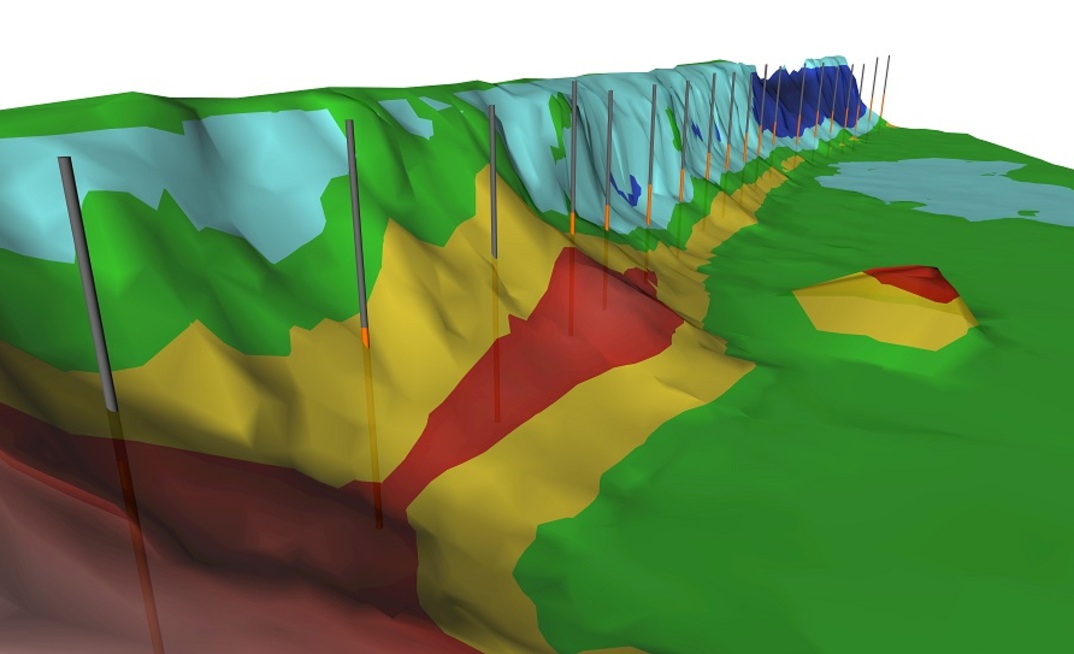

"Maptek users are working within a technical platform which is able to link geological and orebody knowledge with planning and engineering tools and operational detail to enable, for example, blasting, grade control, geotechnical risk and production equipment scheduling to be managed all within the one integrated and connected environment.

"Operational equipment such as blasthole drills and explosive loading trucks are connected to the design environment, which in turn is connected to the orebody model and mine plan. Delays and equipment availability are visible in real time and the accuracy of blasting operations has never been better.

"The result is a more productive mine, less waste, better adherence to plan and improved decision support at a number of points in the delivery of the plan. Only by properly modelling, measuring and understanding the interaction between orebody knowledge, planning, design and scheduling and the execution of mine operations in practice can you effectively understand where, and how, improvements can be made.

"Optimisation technology and theory of constraints is also being applied to larger slices of mine operations and operating models. Optimising one discrete piece of a process is not of great value if up or downstream processes are not operating in a fashion to make the most advantage of the optimisation.

"Maptek technology and our integration strategy allow larger components of the mine operational plan to be optimised and more valuable improvements to be made."

Peter Johnson: "Maptek technology and our integration strategy allow larger components of the mine operational plan to be optimised and more valuable improvements to be made"

To hear more from Peter Johnson on real-world technical data connectivity, click here.

Johnson says so-called point solutions, which underpinned Maptek's development, must continue to be as cutting-edge, reliable and ultimately useful (and usable) as ever. A series of new product releases this year will emphasise Maptek leadership in various technical solution market segments. The company's products are used at more than 2,000 sites in 70 countries by a diverse mix of blue chip miners, explorers and developers, consultants and contracting firms.

But many users are asking increasingly for the integration that allows them to work seamlessly between applications.

"When all the data is available at your fingertips, the end point is greater than the sum of its parts," Johnson says.

"Decisions will be informed, current and effective.

"Enterprise connectivity means that multiple users can share data for multiple functions across multiple applications.

"The opportunity is there for us to continue to build this ecosystem where all these tools work together; they can all work on common data, all work on a common interface, and all talk to each other and communicate and share, and when I talk about all these tools I mean from the geological model of the orebody, through to the production results and shipping data - the much talked-about pit-to-port integration and optimisation."

Hardman echoed the view that big customers were ready and in some cases already working with Maptek on full integration of technical product workflows, and insertion into that integrated environment of higher value drivers ranging from the advanced Evolution scheduling tools, to machine learning and neural network inputs.

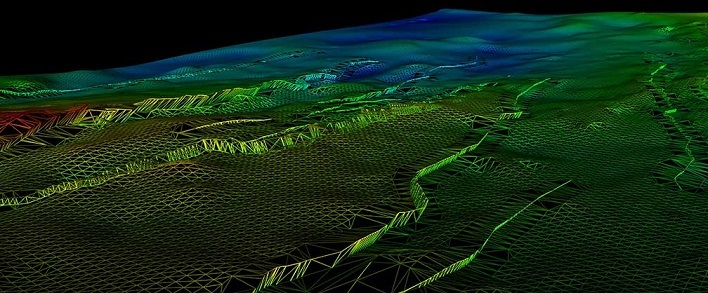

But the generally higher rate of adoption of Maptek's full suite of products - and indeed the breadth of this range - also made the introduction of new high-value ‘tools' and product extensions, such as Vulcan 3D Geological Sculpting and Vulcan Implicit Modelling a more straightforward ‘sell' for the vendor, and more compelling ‘buy' for the user.

"We do play in a wider space than a lot of competitors and we find that it is really advantageous in terms of the value proposition," Hardman says.

"There are multiple software packages available in geology, in design and planning, and there is a lot of room there for data degradation when you're trying to transfer data between these packages, and we see that all the time.

Maptek Vulcan is a globally recognised brand

"But if someone can use Maptek from here, at the exploration stage, all the way over here, to mine planning and all the way into the operational space with scheduling, mine measurement and drill and blast management, we can really provide more efficient and connected solutions that allow better workflow, and really mitigate a lot of that data degradation that can happen."

Hardman says Vulcan 3D Grade Control Optimiser, which turned a typically manual task into an opportunity to automate the process while creating more accurate material classifications and minimising dilution, was one of the latest examples of Maptek's insatiable appetite for innovation.

"If you are trying to optimise your grade control process … with what has been a fairly basic and notoriously inaccurate methodology, you can obviously get sub-optimal results. Here again we've got a smart algorithm and a product that automates and optimises that grade control process, and we've done trials with several large clients who are finding about 3% or better returns on their grade control optimisation," he says.

"So a lot of big dollars to be picked up there."

BlastLogic, a big success for Maptek so far, is another example of the company transferring class-leading domain expertise into an extensional field.

"BlastLogic is providing analytics and digitalisation of near real-time blasting data, and that's the direction in which we're heading," says Hardman.

"It's had a high rate of adoption - more than 40 sites in the last couple of years - and we've now got large clients evaluating multi-site implementation here. It's another step towards that mine-actual operations centre that we're working on with these clients."

Johnson says there is an increasing desire among large and smaller miners to standardise operating systems and platforms to help solve significant business "problems" and drive better outcomes.

"We've had one global large miner that has standardised on BlastLogic in the blasting space, based on the opportunity to fix a business process, systematise it, and build a template that says here's how we are doing blasting, here's how we're measuring performance, and here's the information we're going to be needing to manage the process," he says.

"There is an appetite there for standardisation and if the problem gets big enough there is a need.

"It can be complicated in big organisations with all the different people and different agendas, but it can be and is being done, and the technology to enable and see and drive the value is more accessible."

ABOUT THIS COMPANY

Maptek

ESTABLISHED:

- 1981

HEAD OFFICE:

- 31 Flemington St, Glenside, South Australia 5065

- Telephone: + 61-8-8338-9222

- Email: info@maptek.com.au

- Web: www.maptek.com/