By helping to eliminate process constraints and making the required changes stick, we helped our mining client add $99 million to their bottom line.

The world-class team at a new $4 billion gold mine had made significant progress towards meeting their ramp-up targets.

The Company Executive and Mine Management team identified an opportunity to increase project NPV by compressing the ramp up timeframe and decided to enlist Proudfoot's expertise and a new way of working.

The Proudfoot methodology engaged the end-to-end process from mine planning to processing, to manage constraints, bringing consistent results and moving complexity out of operations and into planning.

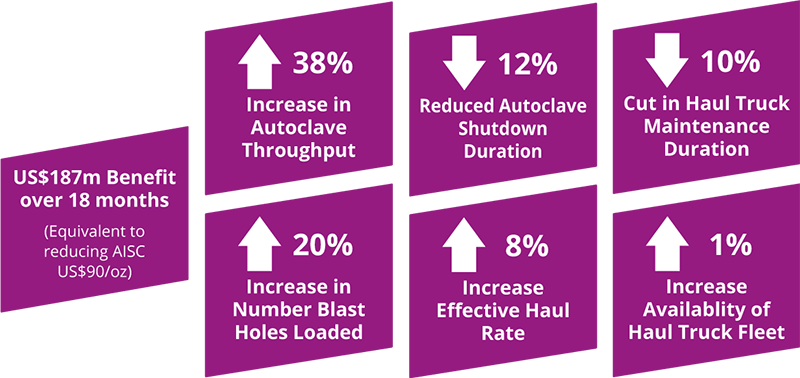

This impacted Safety performance as well as productivity and operational performance. Within six months, output improved 17 percent, adding $99 million of annualised income and building a operational foundation for further on-going improvements.

This gold mine is the largest gold mine in the Americas by production, and second largest in the world. They have a well-resourced, top-flight technical and executive team and they knew they could achieve.

"We took only six months to see those results instead of four years" - MINE COO

A significant reduction in borrowing costs if its ramp-up schedule was accelerated. Despite their best efforts and steady progress, output remained inconsistent. The team asked themselves "what if they could" accelerate achievement of stable production and increase the throughput to nameplate?

Both the group COO and mine Executive General Manager were aware of the positive NPV impact of achieving nameplate capacity early. Both had previously worked with Proudfoot and knew our mining team reputation for collaborating with clients to quickly achieve lasting results. They asked us to partner with mine management to identify how the team could stablise production, accelerate the operational ramp up and achieve or exceed nameplate production.

The initial constraint was rapidly identified as the plant's autoclaves circuit. Joint analysis identified the cause as high sulphur variability in the plant feed. This challenge was compounded by the need for to develop operator, supervisor and planner skills, along with a need for detailed and wider planning coordination across the mine-to-mill process. Many of these issues are typical of ‘big ticket' mining projects, where international and multi-cultural teams are often working together for the first time.

"To achieve what we wanted demanded more than just a technical approach. Working with Proudfoot meant we took only six months to see results instead of four years if we'd continued alone."

Site management had made progress through plant commissioning and start-up to increase volumes processed. In fact, some shifts were beating plan. But many shifts fell short, reducing average tonnes-per-day processed through the plant; throughput was not stable, Sulphur content variability prevented optimum autoclave processing.

Together, the teams agreed that improving ore delivery and reducing variability would unblock production constraints.

Working together we rapidly prototyped ideas to establish viability of a solution - within four weeks the team had proof of concept. They determined the solution would allow the mine to meet its targets, provide a foundation for future growth and rapidly enable the project to be self-funding.

This would not only assist the new business operationally but have the additional financial benefit of reducing borrowing costs and increasing project NPV.

With the analytics and pilot complete, the business case agreed and alignment around the plan, a joint Proudfoot/mine team began work. We complemented our client's technical knowledge and testing skills with our own global mining team's experience. And we added additional skills in site wide integrated planning, operational constraint management, maintenance planning and scheduling, Enterprise Arial Mapping - our end-to-end process improvement methodology, operator and supervisory skills development.

Working together with the management team, we introduced key changes in work practices that would last, as well as changing the daily, site-wide behaviours of operators, supervisors and managers.

Three, jointly-resourced teams began improving ore-feed stability, maintenance planning and equipment reliability. A fourth team provided supervisor and manager skills training, coaching and regular site-wide communications.

A joint project leadership governance team, led by the executive general manager and the group COO, kept the teams on track, helped remove barriers and drove up participant engagement. Working to drive sustainable change, cross-departmental teams agreed common goals. They also drew up agreements to formalize and strengthen commitments between work groups.

Cultural intelligence plays a key part in any safe, successful and lasting change, and particularly so in large scale capital projects in areas new to mining. This means working thoughtfully to support the client and its host country culture and diverse longer term goals.

"A key outcome was moving complexity out of the operations and into the planning process. Once done, operations leaders and supervisors could focus on executing a safe, detailed plan instead of reacting to variability."

Bilingual coaching played an essential role in effectively engaging the mostly Anglophone expatriates and majority Hispanic workforce. Upskilling the latter, building our client's internal capability to conduct future projects alone and reducing the need for expats were all high-level goals.

Six months in, the working culture at the mine had changed markedly. It

now revolved around a set of higher key performance indicators, agreed through discussion and ultimately worker consent. The results achieved in just a few months are impressive.

Our client met the lender's test, hitting the sustained volume target six months earlier than planned. Our client project sponsor characterised this ramp-up result as an outstanding success, commenting:

Today our client has the capability to go it alone. With repeatable, proven management systems in place, efficiency improvement is now part of the workforce's DNA.

Our change management and coaching skills were used to really make change stick. To underpin the change, we developed and introduced new management systems and tools to better lead both operational improvement and safe productive operations.

How did we use these skills to achieve significant changes in results?

- We gained alignment on the improvement objectives, scope, and timeline, from all leaders and process owners across the mine-to-mill process, including maintenance.

- Following that alignment and working with site leadership, we defined

a future-state model for ore-feed delivery. This enabled the leadership team to set higher autoclave throughput milestones.

-

We revised mine-to-mill planning to coordinate across the entire process to reduce variability of input ore quality.

-

To support this, we introduced shift-level and daily detailed planning across the operations and maintenance process to ensure activities were coordinated.

Call Us

To secure significant productivity you must engage your people to be successful.

To find out how we can help please contact Pamela Hackett, CEO, email: pamelahackett@proudfoot.com

ABOUT THIS COMPANY

Proudfoot

We design, implement and accelerate operational and digital transformation through people. Realizing tomorrow's results, today.

HEAD OFFICE:

- 4th Floor, St Paul's House, 10 Warwick Lane, London EC4M 7BP, United Kingdom

- Tel: +1 470-548-6489

- Web: www.proudfoot.com

- Email: info@proudfoot.com