For more than 140 years, the London Metal Exchange (LME) has set requirements for metallurgical standards and shapes when approving brands that can be used to deliver against LME contracts (and consequently, the brands that make up the LME price - and more broadly, those which are viewed as deliverable in many physical supply contracts).

More recently, demand for responsibly sourced metal is such that we have extended our requirements to include conditions for how metals are sourced. As the world centre for industrial metals trading, we now have a key role in facilitating the adoption of globally accepted responsible sourcing principles, and we are pleased to be able to offer the mining community a clear path to compliance.

Our users will be able to take delivery of metal from any one of our listed warehouses and be assured that it meets those principles, and that the price they paid reflects the value of responsibly sourced metal. And similarly, the status of ‘LME-listed' will provide confidence to downstream users that the metal meets appropriate ethical (as well as metallurgical) standards, hence streamlining responsible sourcing compliance for smelters, refiners and their upstream mining suppliers.

Our responsible sourcing rules are underpinned by the OECD's Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas (‘OECD guidance') and they leverage the existing good work within the industry through utilising OECD-aligned metals standards that are already available (or in development) to conduct due diligence on brands that operate in conflict-affected and high-risk areas (CAHRAs).

LME-listed brands will now also be required to hold a valid certificate for ISO 14001 and OHSAS 18001/ISO 45001 (or equivalent), to ensure that environmental and occupational health and safety management systems are firmly embedded in the operations of all brand-producing companies; both of which represent important steps in progressing the global sustainability agenda.

We are fortunate that since their publication, our rules have been widely embraced by trade associations, which continue to provide invaluable assistance in forging the industry-wide dialogue necessary to ensure all of us in the metals and mining world are taking the right practical steps towards this common ethical goal.

Given the importance of practicality in reaching this goal, this paper provides further guidance to mining industry participants on how to select the right track towards responsible sourcing compliance.

Which track should your brand take?

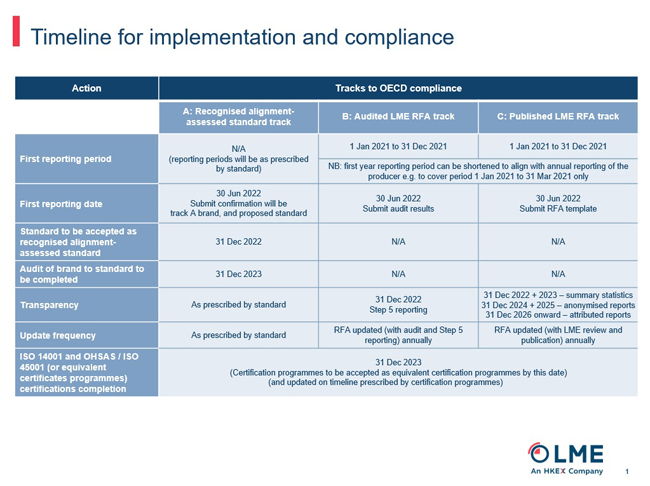

There are three possible routes to achieve LME and OECD compliance: A, B and C. Regardless of the track chosen, all brands will be required to:

- Complete step 1 (establish company management systems) and step 2a (identify supply chain risks). The LME has provided a template to assist with the completion of this process (the Red Flag Assessment, or RFA template)

- Complete ISO 14001 (environmental management systems) and ISO 45001 (occupational health and safety management systems) or equivalent certification.

Track A

Track A is likely right for you if:

- You have identified red flags in your supply chain (for example, you operate in a CAHRA)

- You have not identified any red flags, but would like to use a standard to demonstrate compliance in achieving the relevant OECD steps for your brand

- You would like to have the guidance and support of a standard that can provide you with information and tools to achieve compliance

- You would like to voluntarily complete all five OECD steps to ensure you are embodying best practice in the responsible sourcing field.

Step-by-step guide:

- Identify a standard and submit this choice to the LME by June 30, 2022. This standard can be internal or external

- Ensure that your standard (internal or external) is fully or conditionally OECD-alignment assessed. When a standard is conditionally alignment assessed, this means that it has completed the first step for OECD alignment (standards alignment) and is on track to complete the second step (implementation alignment). The decision on conditional alignment, as with full alignment, will be based on audit findings, with the LME retaining final discretion

- In line with the chosen standard, you must demonstrate compliance by completing the relevant steps (in line with the OECD five-step framework) for your brand, depending on the results of your supply chain risk assessment (step 2a). For reference, the other steps are as follows:

- Step 2b - assess risks of adverse impacts in supply chain

- Step 3 - design and implement a strategy to respond to identified risks

- Step 4 - carry out independent third-party audit of supply chain due diligence

- Step 5 - report on supply chain due diligence

- You will need to provide the LME with an audit or suitable assurance report by December 31, 2023:

- External standards will each have audit review processes with which you will need to comply

- Internal standards will require third-party audit or assurance review (the LME will provide a list of suitable assessors on its website in the near future)

- In order to remain compliant:

- Those using an external standard will have to keep up-to-date per requirements of the chosen standard

- Those using internal standards will have to update their audit or assurance report at least every three years, or following material change to the standard or the OECD Guidance.

Track B

Track B is likely right for you if:

- You have not identified red flags in your supply chain (for example, you do not operate in CAHRAs); and

- You do not wish to use a standard to demonstrate compliance

- You would like your RFA to be independently audited (instead of audited by the LME and published - track C).

Step-by-step guide:

- Download the LME RFA template from the LME website and complete it - if red flags are identified, contact the LME to let them know you will be taking track A instead

- Your first reporting period will be from January 1, 2021 to December 31, 2021 (although there is flexibility to align your reporting period with your existing company reporting periods if preferred)

- Select an independent third-party auditor to assess the validity of your RFA - the LME will maintain and publish an approved list of auditors

- The chosen auditor will confirm that the relevant supply chain contains no red flags and will then submit these results to the LME for review by June 30, 2022;

- The LME will confirm that the audit report is of suitable detail and quality and then confirm compliance

- You will be required to update your RFA audit annually or if your supply chain changes.

Track C

Track C is likely right for you if:

- You have not identified red flags in your supply chain (for example, you do not operate in CAHRAs); and

- You do not wish to use a standard to demonstrate compliance

- You would like to ensure your brand is exercising best practice in terms of transparency.

Step-by-step guide:

- Download the LME RFA template from the LME website and complete it - if red flags are identified, contact the LME to let them know you will be taking track A instead

- Your first reporting period will be from January 1, 2021 to December 31, 2021 (although there is flexibility to align your reporting period with your existing company reporting periods if preferred)

- You will be required to submit your RFA by June 30, 2022 - the LME will confirm receipt

- The LME will review the RFA and revert with any questions. Once the LME has approved the RFA, it will be published on the LME website in a phased approach: in 2022 and 2023, the LME will provide summary statistics; in 2024 and 2025, the LME will publish anonymised reports; and from 2026 onwards, fully attributed reports will be published

- You will be required to update your RFA annually or if your supply chain changes.

Changing tracks

If there are no red flags in your supply chain, you can freely move between tracks A, B and C, as long as you notify the LME. If you identify red flags in your supply chain, you must take track A.

ABOUT THIS COMPANY

London Metal Exchange

HEAD OFFICE:

- 10 Finsbury Square, London, EC2A 1AJ

- Tel: +44 (0)20 7113 8888

- Web: www.lme.com/