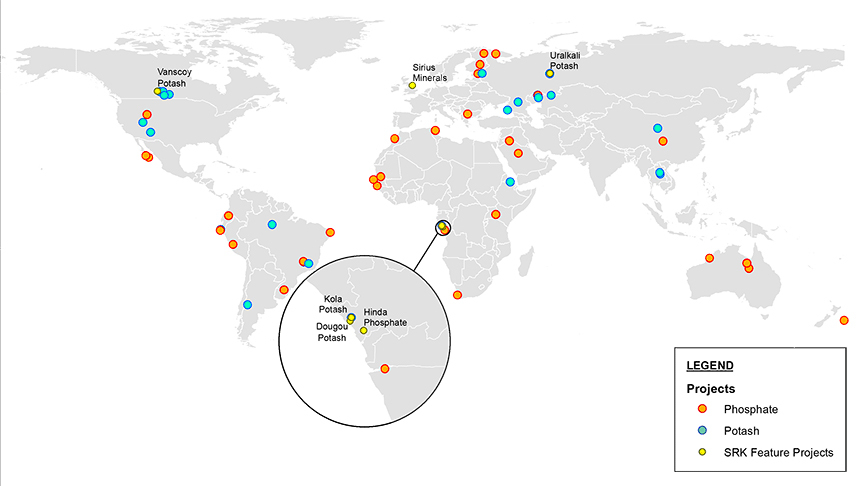

Low potash and phosphate prices in 2016 have put further pressure on companies to seek ever improved outcomes from their mineral resources. SRK's expertise helps clients achieve best practice and efficiencies in their projects in order to improve value, advance stakeholder engagement, provide confidence to investors, and help ensure worker safety.

Relevant experience in recent projects

Sirius Minerals: SRK has worked with Sirius Minerals on its polyhalite project in North Yorkshire, UK, since 2010, authoring the initial mineral resource estimates, developing mine designs and schedules, geotechnical engineering to Pre-Feasibility Study level, and preparing ore reserves estimates in accordance with the JORC Code. Subsequently, SRK progressed these aspects in order for Sirius Minerals to develop the project to a Feasibility Study level, enabling Sirius Minerals to mandate a consortium of leading international banks to help it secure a US$2.6 billion debt facility.

SRK has developed the planned room and pillar mining method for workings 1,500m below ground level, utilising continuous miners and blasting of rooms up to 40m high in the thickest areas of the resource, to facilitate the planned production of some 10 million tonnes of polyhalite per year. SRK's mining team has worked with equipment manufacturers and other specialists on the equipment design, layout and costing for the project.

Uralkali: SRK undertakes annual audits of the Mineral Resource and Ore Reserve statements for Uralkali and reports these in accordance with the JORC Code. Uralkali is a leading global potash producer with five operating underground mines, six potash plants, one carnallite plant, and licences covering additional deposits with the potential for future development. SRK's involvement with Uralkali commenced with preparation of competent persons reports for the original full listing of OJSC Uralkali on the London Stock Exchange in 2007 and also for its subsequent merger with OJSC Silvinit in 2011. This work included full technical, environmental, and economic due diligence of the operating and exploration sites located in Berezniki and Solikamsk, Russian Federation, and producing audited mineral resource and ore reserve statements reported in accordance with the JORC Code.

SRK undertook a separate commission that includes a comprehensive review of the methods used at Uralkali to help prevent groundwater inrush. A quantitative analysis of potential mine failure risk for each of the operating mines was also completed using a GIS-based composite hazard model.

Vanscoy: SRK has been working with Agrium Inc. to expand its rock mechanics programme at Vanscoy mine, Canada, to test mining methods more suited for the depth and changes in geology as mining extends north and south. A centralised database of rock mechanics data is being collected using tablet technology that incorporates 3D mine plans and instrument locations, enabling direct mapping of geological features onto the tablet. SRK created and calibrated several numerical models with mine data to estimate the performance of different mining methods. A trial panel, heavily instrumented to measure ground movement, was successfully completed in early 2016. Data collected were used to calibrate the predictive models to actual panel performance. The resultant mine panel design has proven very resilient to the changes in geology and has allowed a significant increase in ore recovery from parts of the mine impacted by local geological variation.

Hinda: In 2015, SRK completed a multidisciplinary Feasibility Study for Cominco Resources Limited's Hinda phosphate project, Republic of Congo. SRK was responsible for authoring technical studies for open pit geotechnics; hydrogeology and hydrology; mining geochemistry; tailings; and an accompanying technical review of disciplines conducted by others in support of the ore reserve declaration in line with the guidelines of the JORC Code. Hinda is an elongated deposit between 300m and 800m wide and extending for more than 20km. The project lends itself to strip mining techniques and provides the opportunity to backfill waste. A fully integrated ore and waste management strategy, production schedule and plan, applying a hybrid mining method employing semi mobile in-pit crushing and conveying, was defined. Design for the transient mining area was integrated with dewatering and surface water management design components and a linked development plan with associated costing structure (capital and operating) established.

Wa'ad Al-Shamal (previously the Umm Wu'al) Phosphate Project, Bankable Feasibility Study ("BFS") on behalf of Jacobs UK Limited, for Ma'aden Phosphate Company, Kingdom of Saudi Arabia.

The Wa'ad Al-Shamal Phosphate Project presents a conventional drill and blast mining operation with a fully integrated waste rock back fill strategy. The study considered the project specific primary crushing requirements and developed a dry stack tailings storage facility design in support of minimising the project water requirements. As part of the study, SRK provided on-site supervision for the water supply pumping tests and developed a hydrogeological model to support the project water balance and water extraction permitting process. The study was approached in three streams: 1) where SRK performed the technical studies and authored the accompanying sections of the BFS (geology and Mineral Resources; mining and Ore Reserves; open pit geotechnics; hydrogeology and water supply; geochemistry; primary crushing; tailings and waste rock); 2) technical review of disciplines conducted by others in support of the Ore Reserve declaration (mineral processing, environmental and social and financial modelling); and 3) capital and operating cost estimation for the mining study and cost estimate design parameters for the primary crushing and tailings. SRK was responsible for the successful delivery of the mining related disciplines which included the development and declaration of Mineral Resources and Ore Reserves reported in accordance with the guidelines of the JORC Code.

Kola and Dougou: SRK has undertaken environmental and social impact assessments (ESIAs) on behalf of Elemental Minerals Ltd for both the Kola underground mine project (2011 to 2013) and the Dougou solution mining project (2015 to 2016) in the Republic of Congo. Both projects sit within the Sintoukola potash permit area, with the Kola deposit being high-grade sylvinite (33.1% KCl) and the Dougou deposit being high-grade carnallitite (20.7% KCl). Working closely with the project engineers, SRK took the lead role in the ESIA processes, managing in-country consultants and international sub-consultants to deliver on budget and on schedule. SRK's technical specialists also undertook the water baseline and impact modelling studies and compiled the conceptual closure plan and cost estimate.

Key consultancy areas that improve outcomes for clients:

- Rock mechanics programmes and mine planning: improved ore recovery in underground potash mines can be achieved through comprehensive rock mechanics programmes, particularly where geological variability exists. SRK provides operational support to improve safety and efficiency in such environments.

- Creep modelling: 2D numerical modelling and 3D time dependent creep modelling are important to understand the stability of rooms and pillars and assess the magnitude and extent of deformation and surface subsidence above the mine. SRK has undertaken numerous modelling studies for potash projects worldwide to assist in maximising mineral extraction while ensuring mine stability.

- Catastrophic inrush: underground potash mines are susceptible to flooding as a result of groundwater inrush. Such events can be catastrophic, sometimes leading to the loss of the mine. SRK has been involved in several studies addressing the risk of mine failure and its mitigation for both operational underground mines and development projects in Saskatchewan, Canada, and the Urals region of Russia.

- Beneficiation: SRK has helped clients optimise the beneficiation processes at potash and phosphate mines; for example, the design of flowsheet methods to improve the removal of impurities such as carbonate minerals and silica. Energy and water conservation are also typical objectives of studies in a highly competitive market.

- Water supply and management: many projects are in locations where water management can be challenging. SRK's water specialists help clients to identify groundwater sources, demonstrate its sustainability, and design optimised water supply well fields that can draw water from aquifers, sometimes many hundreds of metres below ground level.

- Due Diligence: SRK has undertaken numerous due diligence mandates on potash and phosphate projects for both equity raising and on behalf of lending institutions. SRK is able to mobilise multidisciplinary teams to review technical, environmental, social, and economic aspects and provide independent analysis on a project for potential investors.

SRK CONSULTING at a glance

SERVICES

- Feasibility Studies

- ESIAs

- Multidisciplinary Due Diligence

- Independent Engineers Reports

- Mineral Resource and Ore Reserve Reporting

- Competent Persons Reports

- Technical Reports (inc. NI 43-101)

- Mineral Asset Valuation

- Operations Support

Tel: +44 (0) 29 2034 8150

Web: www.srk.co.uk

ABOUT THIS COMPANY

SRK Consulting

SRK Consulting is an independent, international group providing specialised consultancy services. Among SRK's clients are many of the world's mining companies, exploration companies, financial institutions, EPCM and construction firms and government bodies.

OFFICE:

- SRK Consulting (UK) Limited, 5th Floor, Churchill House, 17 Churchill Way, Cardiff, CF10 2HH, Wales, UK

- Phone: +44 (0) 2920 348 150

- Fax: +44 (0) 2920 348 199

- Web: www.srk.com

- Email: info@srk.com